Customized Dryer for Thai Client by Shine Machinery Successfully Shipped

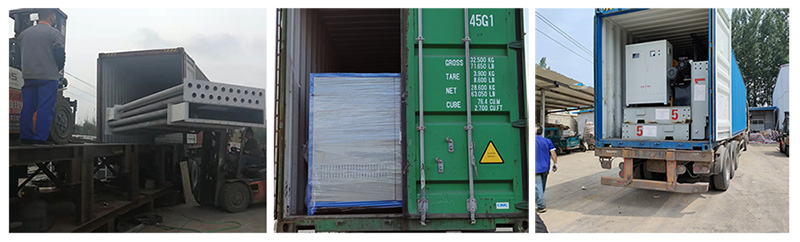

Recently, Shine Machinery successfully completed the installation of a 4 decks stainless steel roller veneer dryer customized for a Thai customer and smoothly loaded it into a container for shipment. This equipment, which embodies the efforts and wisdom of Shine, carries the firm determination of the Thai customer to create high-quality boards and is about to embark on its journey to Thailand.

During the project's advancement, even though Shine Machinery has rich experience and top-notch technology in the production of roller veneer dryers, it still faces numerous challenges and cannot afford to be complacent. As this core drying machine is specially customized for a Thai client, local climate conditions, production demands, and unique working environments must be fully considered, which significantly increases the difficulty of design and manufacturing. From the selection of raw materials to the precise processing of components, and then to the assembly and debugging of the equipment, every step requires meticulous attention to detail.

During the equipment design stage, the company's R&D team had multiple rounds of in-depth communication with the Thai client, accurately grasping their demands: a wide variety of single board sizes, high requirements for single board thickness error, and high demands for the smoothness and cleanliness of the single board. The technicians of Shine applied advanced design concepts and cutting-edge technologies, and in combination with their unique biomass combustion furnace, the entire set of equipment not only met the high-quality requirements for single boards but also had an extremely high energy utilization efficiency. The designers repeatedly optimized the design plan. During the manufacturing process, the workers on the production line adhered to a meticulous and rigorous working attitude, strictly following the high-standard process flow to operate, ensuring that every component of the equipment met the high-quality requirements.

Meanwhile, due to the instability of the global supply chain and the long procurement cycle of some components, the project progress was once at risk of delay. Shine Machinery actively coordinated resources from all parties, closely cooperated with suppliers, closely tracked the production and transportation of components, promptly adjusted the production plan, and made every effort to ensure the smooth progress of the project.

Through the unremitting efforts and tenacious struggles of the Shine Machinery's team, they successfully overcame numerous difficulties and ensured the on-time delivery of the equipment. This not only demonstrates Shine's strong technical capabilities and well-established project management system, but also reflects the company's high regard for customer needs and its firm commitment to fulfilling its promises.

The delivery of this 4-layer stainless steel roller veneer dryer marks a new stage in the cooperation between Shine and its Thai client. We believe that with the support of Shine's high-quality equipment, the Thai client will surely achieve new breakthroughs in the field of board production, manufacturing high-quality veneer cores, and other veneered products, and enhancing market competitiveness. Shine will also continue to uphold the principle of "customer first, quality first", providing outstanding products and services to more global clients, and jointly creating a bright future.