Guizhou Four Deck Veneer Dryer Equipment

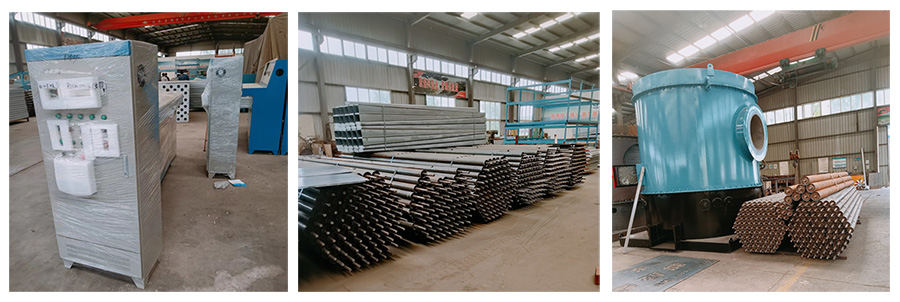

A key milestone has been achieved as the production of a 4-layer veneer dryer, purchased by a client in Guizhou Province, has been completed. The equipment is now prepared for shipment, marking a critical step toward enhancing the client’s veneer processing capabilities. This advanced dryer, equipped with cutting-edge technology, is set to deliver efficient, cost-effective drying solutions tailored to the client’s production needs.

Core Technical Features of the Dryer

The 4-layer veneer dryer is designed to address critical challenges in wood veneer processing, including inconsistent drying quality and high operational costs. Its standout features include:

1. Versatile Biomass Burner

A key component of the system is the integrated biomass burner, which directly utilizes various types of waste wood as fuel. This design not only reduces reliance on traditional energy sources (e.g., coal, natural gas) but also aligns with sustainable practices by repurposing wood residues—such as sawmill scraps, branches, or offcuts—that would otherwise be discarded. The burner’s adaptability to diverse waste wood types ensures stable heat supply, even with fluctuating fuel availability.

2. Intelligent Electric Control & Frequency Conversion System

The dryer is equipped with an automatic electric control and frequency conversion system, a game-changer for precision drying. This system dynamically adjusts two critical parameters based on the veneer’s thickness and moisture content:

Transmission Speed: Slower speeds for thicker veneers (e.g., 2.2mm) ensure thorough drying, while faster speeds accommodate thinner sheets (e.g., 1.5mm) to maintain efficiency.

Temperature: Optimal heat levels (ranging from 150–180°C) are automatically regulated to prevent over-drying (which causes brittleness) or under-drying (which risks warping)

This smart control mechanism guarantees uniform moisture content (0%–8%) across all veneer layers, a prerequisite for high-quality plywood production.

3. Automated Feeding & Collection System

To further streamline operations, the dryer integrates an automatic veneer feeder and collection system. The feeder ensures continuous, precise loading of veneers into the drying chamber, eliminating manual feeding errors and reducing downtime. Meanwhile, the collection system automatically gathers dried veneers, minimizing handling labor and ensuring timely transfer to subsequent production stages (e.g., gluing, pressing).

Benefits for the Guizhou Client

For the Guizhou-based client, this dryer promises transformative improvements:

Enhanced Efficiency: The combination of the biomass burner, intelligent controls, and automation reduces drying time per batch by 30% compared to traditional systems, enabling the client to meet tighter production deadlines.

Cost Savings: Labor costs are significantly cut thanks to automated feeding and collection, while the biomass burner’s fuel flexibility lowers energy expenses by 20%–25%.

Quality Consistency: The system’s precision in moisture control and temperature regulation ensures that every veneer sheet meets the client’s strict quality standards, reducing rejects and rework.

Preparing for Shipment & Next Steps

The dryer is now undergoing final quality checks, including testing the biomass burner’s combustion efficiency, calibrating the frequency conversion system, and verifying the automated feeder’s accuracy. Once approved, it will be securely packaged and shipped to the client’s facility in Guizhou.

“Our team is confident this dryer will exceed the client’s expectations,” said a representative from the manufacturing company. “By integrating sustainability, intelligence, and automation, we aim to empower Guizhou’s woodworking industry with tools that drive growth and competitiveness.”

Upon delivery, the client will receive on-site training for operators, covering system setup, maintenance, and troubleshooting. The manufacturer will also provide ongoing technical support to ensure long-term operational success.

This shipment marks another step forward in the company’s commitment to delivering innovative, client-centric solutions for the global woodworking market.