If you are looking for an efficient, reliable, and economical solution to meet veneer production needs, you must not miss Shine's veneer production line product series!

A veneer is a thin slice of wood made by rotary cutting, slicing, or peeling the log. It is used in furniture and decoration, but it is primarily the main ingredient in the making of plywood and LVL. If the quality of wood veneer is very good, the end product, like plywood and furniture, will be of good quality, too, which will be very helpful for your business.

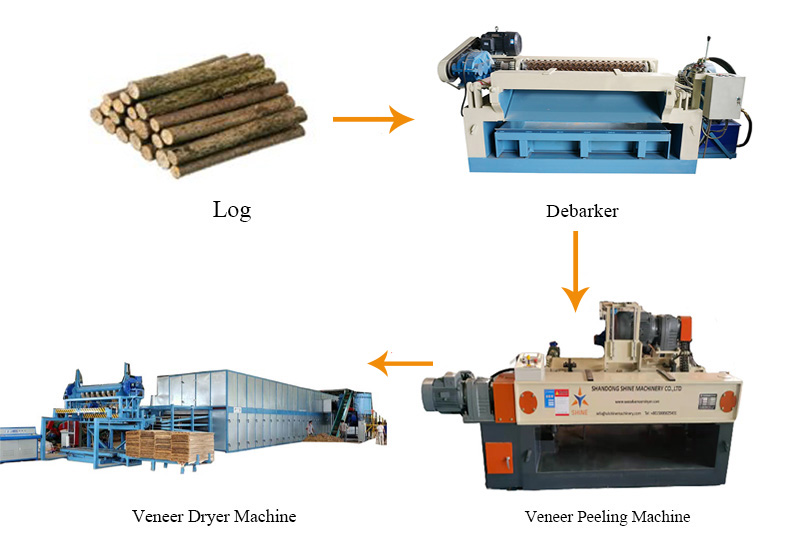

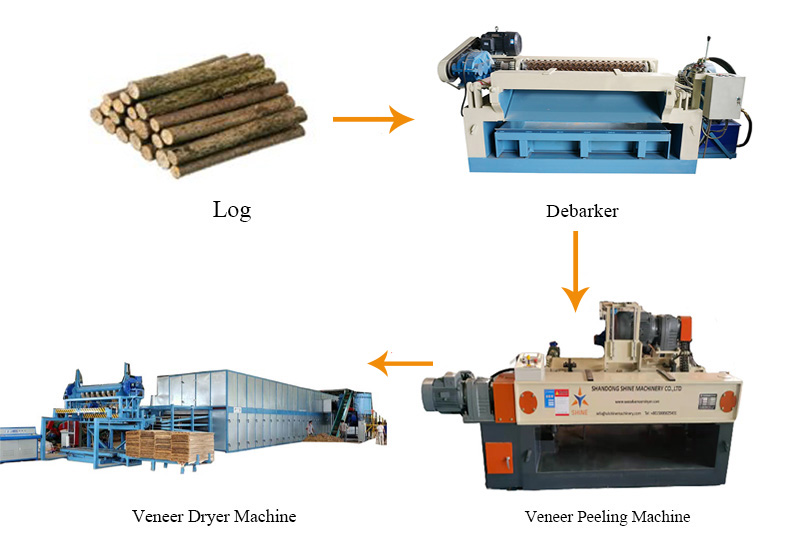

The production of veneer consists of several phases, from handling and peeling logs to drying and patching the resulting veneer. Every phase requires its specific machinery. We have perfected each step of the production both technologically and process-wise to create the most optimal veneer needed. Our machines can create veneers out of all wood species.

Shine has been delivering lines and machines for veneer production needs. We know the most crucial points of every process phase, from log handling to high-quality end products. With us, your veneer production process starts with the market’s most precise and effective log handling.

A veneer peeling machine is necessary for producing wood veneer. The principle of the veneer peeling machine is to rotate a wood log under the driving of a motor and process the wood log into pieces of wood veneer.

First: Soften Log

If your wood is very hard, it is better to put the log into the water before the peeling process to cut it into a smooth veneer of even thickness.

Second: Wood Debarker/log debarker

The wood log debarked processes wood to remove bark and make it round. Wood debarking is easy to operate and has a simple structure. The forward and back of the hydraulic cylinder finish the debarking work.

Third: Veneer Peeling Machine/veneer lathe machine

The spindle-less veneer peeling machine consists of a machine frame, rollers, motors, an electric box, and a CNCa CNC screen. After setting the veneer thickness and width through the CNC screen, inserting the log, and opening the starting button, the veneer machine will start automatically working. As the peeler wood rotates against the knife, it is peeled into veneer.

Different veneer peelers, different configurations.

If the veneer machine is for peeling softwood like poplar, then the machine configuration is common and need not require high power. The power of the veneer peeling machine also need not be too great because softwood is easier to process.

But if your wood log is hardwood, like beech, birch, or acacia wood, then the veneer peeler must be strong enough, more powerful, and heavy-duty to keep the wood veneer thickness accurate and balanced.

The speed, thickness range, structure, and other characteristics of the veneer peeling machine will be different.

The standard size of the veneer peeling machine is 4 feet (max log length 1300mm) and 8 feet (max log length 2600mm), which can also be customized according to your conditions.

Fourth: Veneer Dryer Machine

Different configurations for different needs can be customized according to customer needs, providing quality assurance, installation, and after-sales service.

The whole machine's power is reduced by 30%, saving energy and electricity. It is easy to operate and cost-effective.

Good drying effect: After drying, the moisture content of the veneer is uniform and smooth, without wrinkles or end ripples or cracks, and the surface is in a good glued state.

Heat sources: thermal oil, natural gas, steam, electricity, Shine's patented biomass burner, etc.

The Factory

Shandong Shine Machinery Co., Ltd is a large-scale manufacturer specializing in R&D of wood veneer drying machines and veneer sheet peeling equipment. With decades of growth, Shine Machinery has continuously improved its equipment based on customer feedback. From our first dryer in 1999 to today's fourth generation of the eco-friendly veneer production line, we are dedicated to relentless innovation and providing superior solutions.

Exhibition and Customer Visiting

Our Services

Pre-sale services:

1) Provide the free consultation of all veneer production line

2) According to the client's special requirements, a reasonable plan and free design should be offered to help select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas install and debug the equipment.

3) Train the first-line operator.

After-sale services:

1) 24 hours online service.

2) Provide the VIDEO with the ability to install and debug the equipment.

3) Provide technical exchanging. Door-to-door service is possible.