Shine Veneer Revolutionizes Industry with Fully Customizable Veneer Dryer, Offering Unmatched Tailoring Down to Every Component

Sub-headline: Shine Veneer Dryer sets a new benchmark in wood processing by delivering 100% bespoke drying solutions, where every bolt, chamber, and control is engineered to precise client specifications.

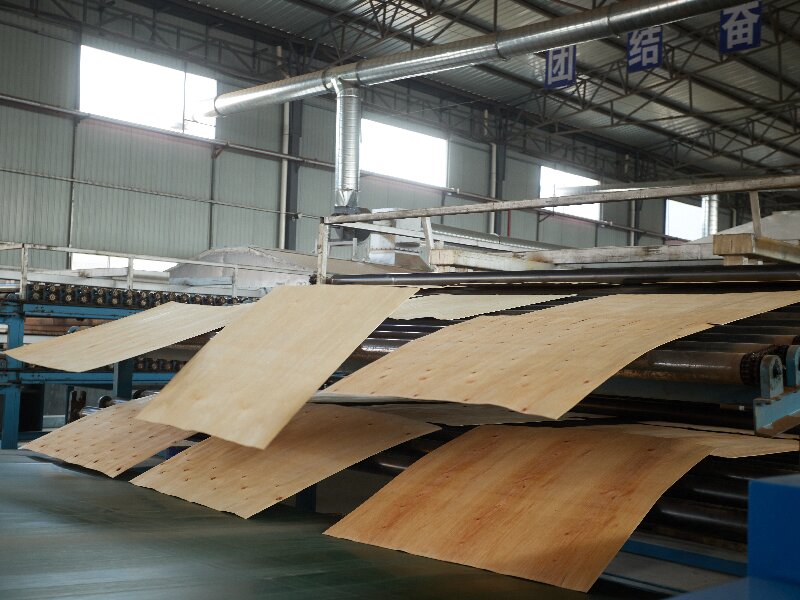

Dateline: SHANDONG, China – In an industry often constrained by off-the-shelf, one-size-fits-all machinery, Shine Veneer Machinery Co., Ltd. is disrupting the status quo with its groundbreaking, fully customizable Veneer Dryer. Moving far beyond basic parameter adjustments, Shine Veneer offers an unprecedented level of engineering partnership by designing and manufacturing dryers in which every component, system, and dimension is tailored to the unique realities of each client’s operation. This commitment ensures not just compatibility but optimal synergy between the machine and the manufacturing environment, maximizing efficiency, yield, and return on investment.

For decades, veneer producers faced a difficult choice: adapt their production flow, factory layout, and raw material specs to standard dryer dimensions and capabilities, or invest in prohibitively expensive, semi-custom solutions with limited flexibility. Shine Veneer eliminates this compromise.

"Standardization has its place, but in high-precision, high-value processing like veneer drying, the ‘close enough’ approach costs our clients money every day in suboptimal throughput, energy waste, or quality inconsistencies," says Mr. Dennis, Chief Engineer at Shine Veneer. "Our philosophy is simple: The machine must fit the client, not the other way around. From the footprint of the loading bay to the specific moisture profile of a rare wood species, we design from a blank sheet of paper for each project."

The Anatomy of Customization: A Deep Dive into Tailored Components

The Shine Veneer Dryer’s customization permeates every layer of its design and construction:

1. Physical Dimensions & Structural Framework:

Overall Footprint and Layout: The dryer’s length, width, and height are not fixed. They are calculated based on available factory space, ceiling height, and integration points with existing clipping, patching, and stacking lines. Clients can choose a straight-through, multi-pass, or even tiered configuration to navigate spatial constraints.

Chamber Section Modules: Instead of fixed-length chambers, Shine uses modular sections. Clients specify the required drying capacity and conveyor speed, and engineers determine the exact number and length of modules needed to achieve the precise residence time for their veneer thickness and species mix.

Loading/Unloading Conveyor Design: Width, roller spacing, and drive power are customized to match the client’s veneer dimensions (from small furniture pieces to large architectural panels) and the output of their upstream peeling/clipping lines.

2. Heat & Air System Customization:

Heat Source Flexibility: The core heating system can be engineered for steam, thermal oil, direct-fired, or biomass combustion, based on the client’s local energy availability, cost, and sustainability goals.

Airflow Circuit & Nozzle Configuration: The heart of drying uniformity. The plenum chamber design, fan blade size/type (axial vs. centrifugal), motor power, and the pattern/density of jet nozzles are all customized. This ensures perfect airflow velocity and distribution across the entire width and between each deck, whether drying delicate 0.3mm oak or robust 3.2mm poplar.

Ductwork and Baffles: The internal ducting is sized and positioned to achieve the designed aerodynamic profile, with adjustable baffles custom-configured for the expected range of operating conditions.

3. Conveyor System & Internal Mechanics:

Roller & Mesh Belt Specifications: Roller diameter, material (steel, aluminum), surface texture, and bearing types are selected based on veneer type and to minimize marking. For mesh belt dryers, the wire diameter, mesh opening, and alloy composition are specified for durability and minimal imprint.

Drive System: Gearmotor power, reducer ratios, and chain/sprocket specifications are engineered for the total load (weight of wet veneer + conveyor) and required speed range, ensuring reliable, slippage-free traction.

Deck Configuration: The number of drying decks (single, double, multi-tier) is a primary custom variable, directly determining capacity within a given floor area.

4. Control & Instrumentation Suite:

Sensor Placement and Type: Moisture probe type (capacitance, resistance) and quantity, along with temperature/humidity sensor locations, are strategically planned for the client’s specific veneer formats to provide representative, real-time feedback.

PLC and Software Logic: The drying curves and control algorithms programmed into the PLC are not generic. They are developed and refined using data from the client’s wood species, initial moisture content, and desired final MC. The human-machine interface (HMI) can be customized for language, access levels, and data reporting formats.

Automation Integration: The control system is designed with defined I/O points to seamlessly interface with the client’s existing plant-wide SCADA or MES systems.

5. Material & Finish Specifications:

Insulation Package: Insulation material type (mineral wool, rock wool) and thickness are customizable based on the client’s ambient conditions and energy efficiency targets.

Cladding & Structural Steel: The exterior cladding (color-coated steel, stainless steel) and the gauge/grade of structural members can be specified to suit different environmental conditions (e.g., coastal, high-humidity areas) or aesthetic preferences.

The Collaborative Engineering Process

Achieving this level of customization requires a deeply collaborative process:

In-Depth Discovery: Shine Veneer’s engineering team conducts exhaustive consultations and, if needed, site surveys to understand raw material variables, factory logistics, utility infrastructure, and production goals.

Simulation & Proposal: Using advanced modeling software, engineers simulate drying processes and create a detailed, component-by-component proposal and 3D layout.

Co-Design Review: Clients review the design, providing feedback on every aspect before manufacturing begins.

Pre-Shipment Testing: Where possible, critical sub-assemblies or control sequences are tested and verified with the client.

Tailored Training & Documentation: Final documentation and on-site training are specific to the delivered machine’s configuration.

Market Impact and Client Testimonials

This approach has resonated globally. A furniture veneer producer in Vietnam reported a 22% reduction in energy use and a near-elimination of over-dried edges after switching to a Shine dryer tailored for their mixed tropical species. A large panel manufacturer in North America praised the seamless integration of a massive, multi-zone Shine dryer into their automated continuous line, made possible by exact dimensional and control interfacing.

Conclusion: Redefining Value in Veneer Drying

Shine Veneer Dryer’s fully customizable paradigm represents more than just a product; it is a service-oriented engineering partnership. By committing to build dryers where every single aspect—from the macro-scale footprint to the micro-scale specification of a bearing—is dictated by the client’s actual needs, Shine Veneer delivers not just a machine, but a perfectly integrated, optimized drying solution. In a competitive global market where efficiency and quality are paramount, this ability to provide a truly bespoke, precision-engineered dryer establishes a new gold standard, ensuring that the equipment itself is never the bottleneck, but the catalyst for growth and excellence in veneer production.