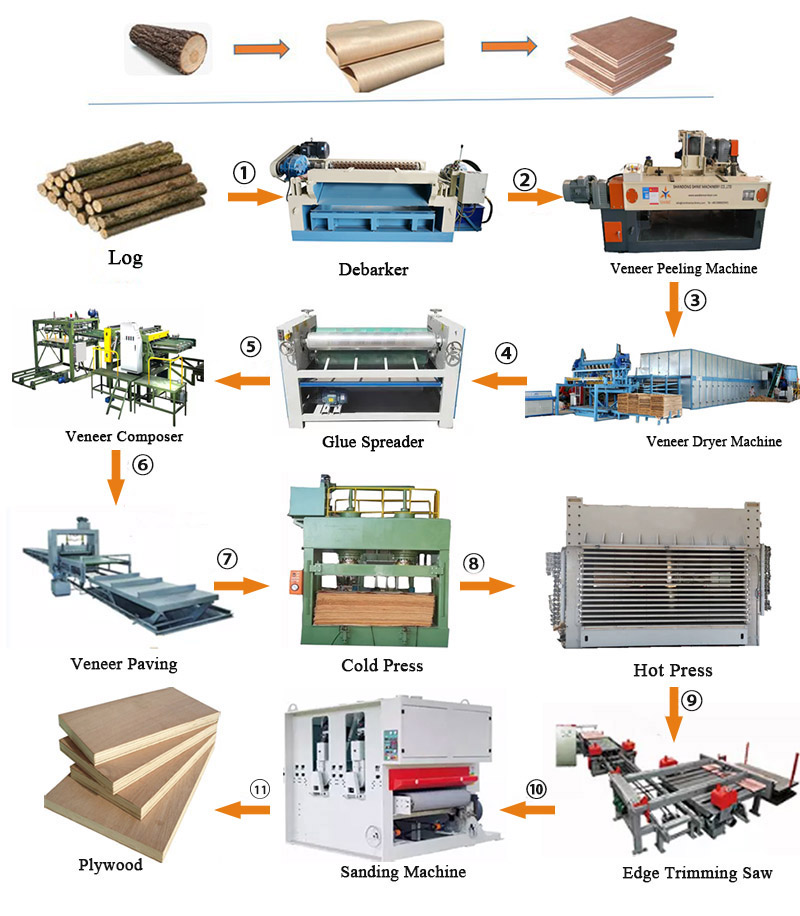

Production steps of plywood

Plywood is made of multiple layers of thin wood sheets glued together, so it starts with log processing. The logs are cut to the right length, then peeled and possibly steamed to soften. Next, they are peeled or sliced into veneers. The veneers need to be dried, then repaired, glued and assembled. After that, they are hot pressed into shape, cooled and cured. Finally, they are trimmed, sanded, inspected and packaged.

The production process of plywood is a multi-step process involving raw material processing, veneer production, gluing and pressing, and post-processing. Here are the main production processes:

1. Log processing

Cut: Cut logs into lengths suitable for peeling or planing (usually 2.6 meters or customized sizes).

Debarking: Remove bark to reduce the impact of impurities on subsequent processes.

Cooking and softening (optional): Soak or cook logs (temperature about 60-80℃) to soften wood fibers for peeling.

2. Veneer production

Pearl cutting (main process):

Fix the softened logs on the peeling machine and rotate to cut out continuous veneers (thickness 0.1-4mm).

Planing (special needs):

For wood with high texture requirements (such as decorative panels), planing is used to obtain veneers with straight grain or special patterns.

The moisture content of the veneer is reduced to 6-12% through a veneer dryer (temperature 70-120℃) to prevent deformation after gluing.

3. Veneer finishing

Sorting and repairing:

Remove defective veneers such as cracks and wormholes, and repair small holes or cracks.

Gluing:

Apply adhesive (usually urea-formaldehyde resin, phenolic resin or environmentally friendly glue) evenly on the surface of the veneer, with an amount of about 100-300g/m².

4. Assembly (overlapping)

Structural design:

Overlap veneers (odd number of layers, such as 3 layers, 5 layers) according to the principle of "vertical wood grain of adjacent layers" to ensure balanced strength.

Symmetrical arrangement:

Use high-quality veneer for the surface layer, and thicker or low-cost wood for the core layer.

5. Hot pressing

Pre-pressing (optional):

Preliminary pressure fixation of the veneer to reduce misalignment during hot pressing.

Hot pressing:

In a hot press (temperature 110-140℃, pressure 1.0-1.5MPa, time 1-1.5 minutes/mm thickness), the adhesive is cured to form a stable board.

6. Post-processing

Cooling and curing:

Naturally cool and stand for 24-48 hours to release internal stress and stabilize the size.

Trimming and sanding:

Cut into standard size (such as 1220×2440mm), sand the surface until it is flat and smooth.

Grading and inspection:

Grade strength, moisture content, and appearance according to national standards (such as GB/T 9846).

7. Special treatment (optional)

Veneer treatment: additional decorative layer (such as veneer, melamine impregnated paper).

Functional treatment: moisture-proof (phenolic glue), fireproof (flame retardant immersion), anti-corrosion (chemical treatment), etc.